Turn Waste Into Wealth

MasterAtlas R3 Returned Concrete Program

Reclaim Value. Reduce Waste. Power Sustainability.

Every day, job sites pour thousands of cubic yards of concrete, and send unused material back to the plant. On average, a single concrete plant receives enough returned concrete each year to pave a 300,000 ft² slab.

Returned concrete used to be:

Wasted Material

An added cost

A growing sustainability challenge

How It Works

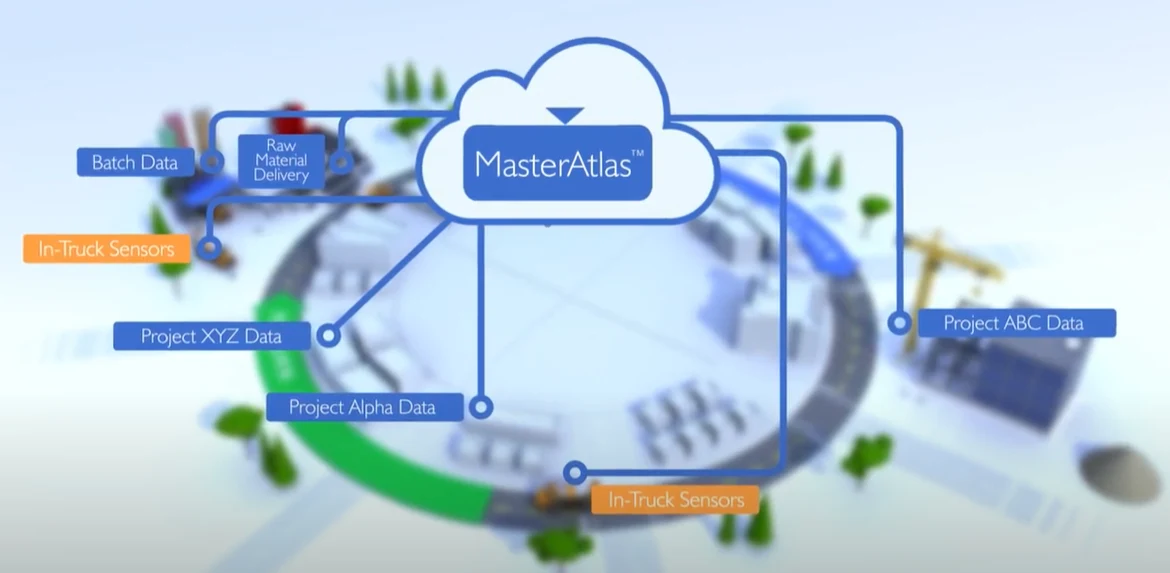

MasterAtlas Tracks Every Return Automatically

When a ready-mix truck leaves the jobsite, MasterAtlas goes to work, analyzing concrete age, mix design, travel time, and reuse potential. Your dispatch team sees live insights. All in seconds.

MasterSet DELVO Makes Reuse Possible

Add MasterSet DELVO to pause hydration, keeping returned concrete fresh, reliable, stable, and ready for reassignment.

Reuse That Pays Off

Every reused yard delivers lower disposal costs, reduced emissions, lower materials cost, and increased profitability.

The R3 Advantage

Full visibility from truck to plant

Data-driven decisions for reuse and reassignment

Real-time dashboards for dispatch and QC

Effortless integration into existing workflows

Improved sustainability metrics

Stronger operational efficiency across the entire fleet